Navigating NEC 2020 for Enhanced Solar Installation Safety and Efficiency

The 2020 National Electrical Code (NEC) has introduced pivotal updates with profound implications for the solar installation industry, notably within section 705.11, governing load side and supply (line) side connections. This comprehensive technical guide delves into the nuances of these updates, offering specialized insight into achieving compliance through advanced engineering practices. Our focus on section 705.11 aims to equip professionals with the knowledge to execute solar projects that meet the latest safety standards and operational efficiencies.

Technical Overview of NEC 2020 Section 705.11

Section 705.11 of the NEC delineates explicit criteria for the integration of solar photovoltaic systems with existing electrical infrastructure. It differentiates between load side connections—those made downstream of the service disconnect—and supply side connections, which interface directly with the utility’s supply network. Mastery of these provisions is essential for the safe, compliant integration of solar energy systems.

Enhancing Safety and Reliability through Precise Guidelines

The updates in section 705.11 introduce stringent requirements for both load and supply side connections. These include enhanced protective measures, precise calculation methodologies for connection capacities, and specific equipment standards. Understanding these technical stipulations is critical for navigating the complexities of modern solar installations.

Strategies for Code-Compliant Load Side Connections

Achieving compliance on the load side necessitates a detailed analysis of the electrical panel’s capacity and the solar system’s output. The NEC mandates that the sum of the breaker ratings connected to a panelboard must not exceed 120% of the panel’s busbar rating when a solar photovoltaic system is connected on the load side. This “120% rule” is pivotal in preventing overloading and ensuring safe operation.

Calculating Load Side Connection Capacity

Technical compliance involves precise calculations that account for the existing load, the panel’s maximum capacity, and the additional input from the solar system. Installers must meticulously evaluate these parameters to ensure the solar system’s contribution does not compromise the panel’s integrity or safety.

Technical Mastery of Supply (Line) Side Connections

Supply side connections offer an alternative pathway for solar system integration, bypassing the limitations of the panel’s busbar rating. This approach requires a comprehensive understanding of the utility’s supply network and the implementation of appropriate interconnection devices.

Implementing Supply Side Connections

The technique for supply side connections involves connecting the solar system directly to the service entrance conductors through a dedicated utility meter or disconnect. Key to this process is the utilization of appropriate junction devices that can safely manage the parallel connection without interfering with the utility’s operations. This requires advanced planning and coordination with local utility providers to ensure adherence to both NEC standards and utility regulations.

Compliance Through Advanced Equipment and Safety Protocols

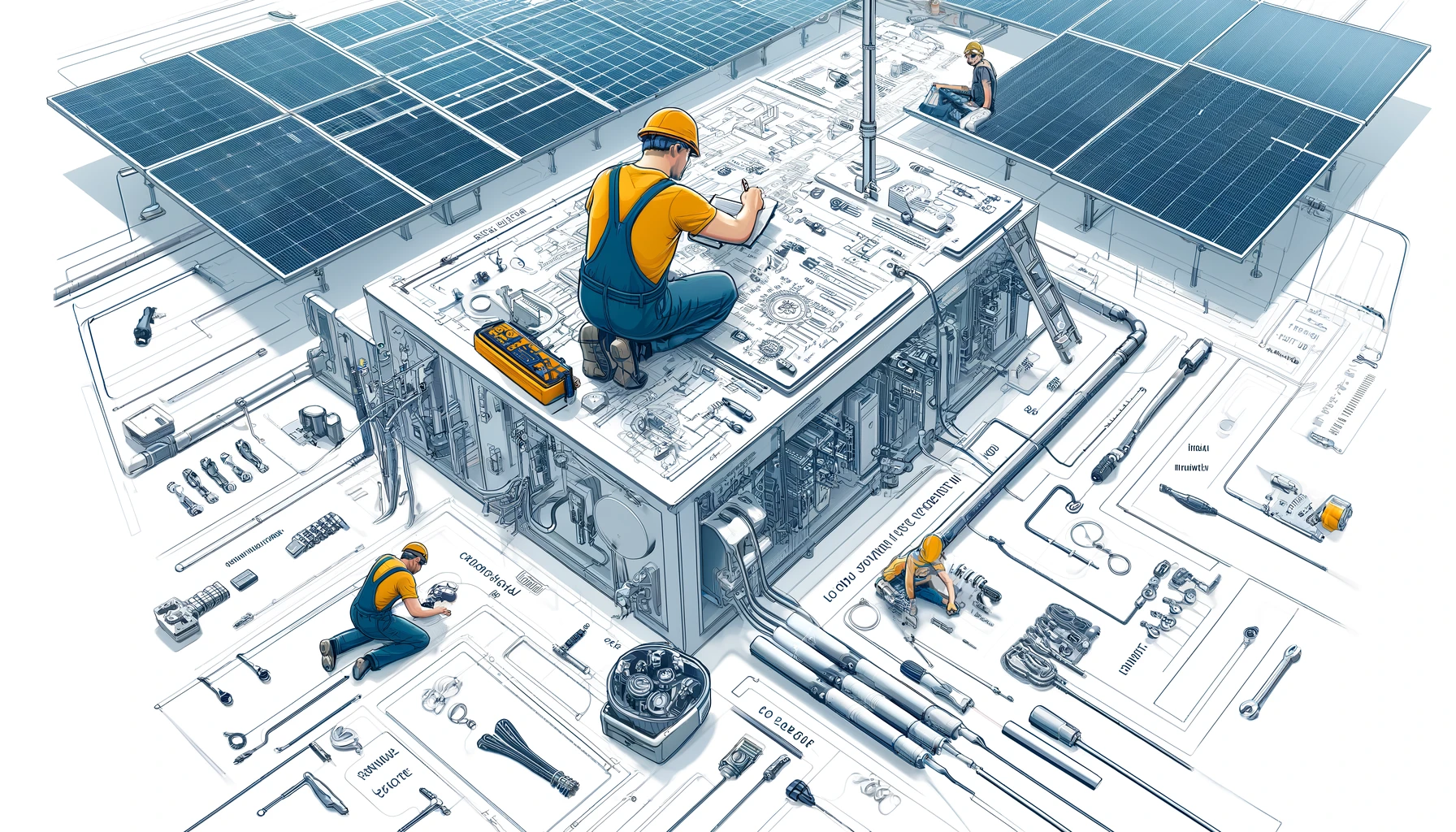

Utilizing state-of-the-art tools and equipment is crucial for NEC-compliant installations. This encompasses the selection of certified electrical components, protective devices, and the implementation of safety measures tailored to the specific challenges of both load side and supply side connections.

Selecting the Right Tools and Protective Gear

The complexity of complying with NEC 705.11 necessitates the use of specialized tools for precise installation and testing. Moreover, the adoption of rigorous safety protocols, including the use of personal protective equipment (PPE), is imperative to protect installers from electrical hazards.

Detailed Documentation and Inspection Readiness

Preparing for NEC compliance inspections requires meticulous documentation of the installation process, including detailed schematics, calculations, and product certifications. This documentation serves as both a blueprint for successful inspection and a record of adherence to code requirements.

Navigating Common Technical Pitfalls

Familiarity with the specific technical challenges of NEC 705.11 enables installers to anticipate and mitigate common pitfalls associated with load side and supply side connections. This includes overcurrent protection, conductor sizing, and the integration of protective devices in accordance with NEC standards.

Advanced FAQs on NEW 705.11 Compliance

- How do I calculate the allowable capacity for a load side connection under the 120% rule?

- To comply with the 120% rule, calculate the panel’s busbar rating and multiply it by 1.2. Subtract the rating of the main breaker to determine the maximum allowable backfeed breaker size for the solar system. This calculation ensures that the total loading does not exceed safe limits.

- Can a solar PV system be connected to a panel without a main breaker using supply side connections?

- Yes, a solar PV system can be connected using supply side connections even if the panel lacks a main breaker. This involves installing a dedicated disconnect on the supply side of the service equipment, ensuring safe and direct integration with the utility’s supply without overloading the internal panel infrastructure.

- What specific protective devices are required for supply side connections to prevent backfeeding?

- For supply side connections, a reverse current protection device is necessary to prevent backfeeding into the utility grid during outages. Additionally, an overcurrent protection device should be installed between the connection point and the main service disconnect to safeguard against potential overloads.

- How do interconnection agreements with utilities affect NEC 705.11 compliance for supply side connections?

- Interconnection agreements often contain specific requirements that exceed NEC standards, such as additional protective devices or specific metering equipment. Compliance with NEC 705.11 must be harmonized with these agreements, necessitating a thorough review and adherence to both sets of requirements to ensure legal and technical conformity.

- In retrofitting an existing electrical system with solar, what modifications might be needed to comply with NEC 705.11?

- Retrofitting may require upgrading the existing electrical panel to accommodate the additional solar capacity, especially if the existing system is near its load capacity. Upgrades could include replacing the main breaker with one of a higher rating, adding a subpanel with a dedicated solar circuit, or installing an external disconnect switch for supply side connections to meet the requirements of NEC 705.11.

Elevating Solar Installation Practices through NEC 2020 Compliance

Adhering to the technical intricacies of NEC 2020, specifically section 705.11, is indispensable for the advancement of solar installation practices. This guide underscores the importance of sophisticated engineering approaches in achieving compliance, ensuring safety, and enhancing the efficiency of solar energy systems.

Leveraging Expertise in Solar Engineering for Compliance and Performance

The rapid evolution of solar installation standards, as exemplified by NEC 2020, demands a partnership with experienced engineering firms adept in navigating these complexities. CNG Solar

Engineering stands at the forefront of this field, offering unparalleled expertise in the technical and regulatory aspects of solar installations. By aligning with our team, you gain access to a wealth of knowledge and resources designed to ensure your projects not only comply with the latest codes but also set new standards for safety and efficiency.

Collaborative Approach for Optimal Results

Engaging with CNG Solar Engineering enables a collaborative approach to project planning and execution. Our methodology involves:

- Thorough Preliminary Assessments: Analyzing site-specific conditions and electrical infrastructure to devise optimal connection strategies.

- Advanced Design and Simulation: Utilizing cutting-edge software to model system performance under various scenarios, ensuring robust design prior to installation.

- Customized Compliance Strategies: Developing tailored solutions that address the unique challenges of each project while adhering strictly to NEC 705.11 requirements.

- Ongoing Support and Consultation: Providing continued guidance throughout the installation process and beyond, ensuring long-term compliance and performance.

Elevate Your Solar Installations with Expert Engineering Support

In the dynamic landscape of solar technology and regulatory compliance, partnering with an expert engineering firm like CNG Solar Engineering is more than a strategic advantage—it’s a necessity for success. Our team is dedicated to empowering your installations with the latest in solar engineering excellence, ensuring that each project not only meets but exceeds NEC 2020 standards.

Whether you’re navigating the complexities of load side and supply side connections or seeking to optimize your installations for peak performance, CNG Solar Engineering offers the expertise and support needed to achieve your goals.

Contact us today to discuss how we can elevate your solar installation projects to the pinnacle of safety, efficiency, and regulatory compliance. Let’s harness the power of the sun together, with precision engineering and code-compliant practices that lead the way to a sustainable future.

Navigating the intricacies of NEC 2020 doesn’t have to be an overwhelming challenge. With CNG Solar Engineering by your side, you’re equipped to face the future of solar installations with confidence and technical prowess. Join us in setting new benchmarks for excellence in the solar energy sector.